Neithalath Lab

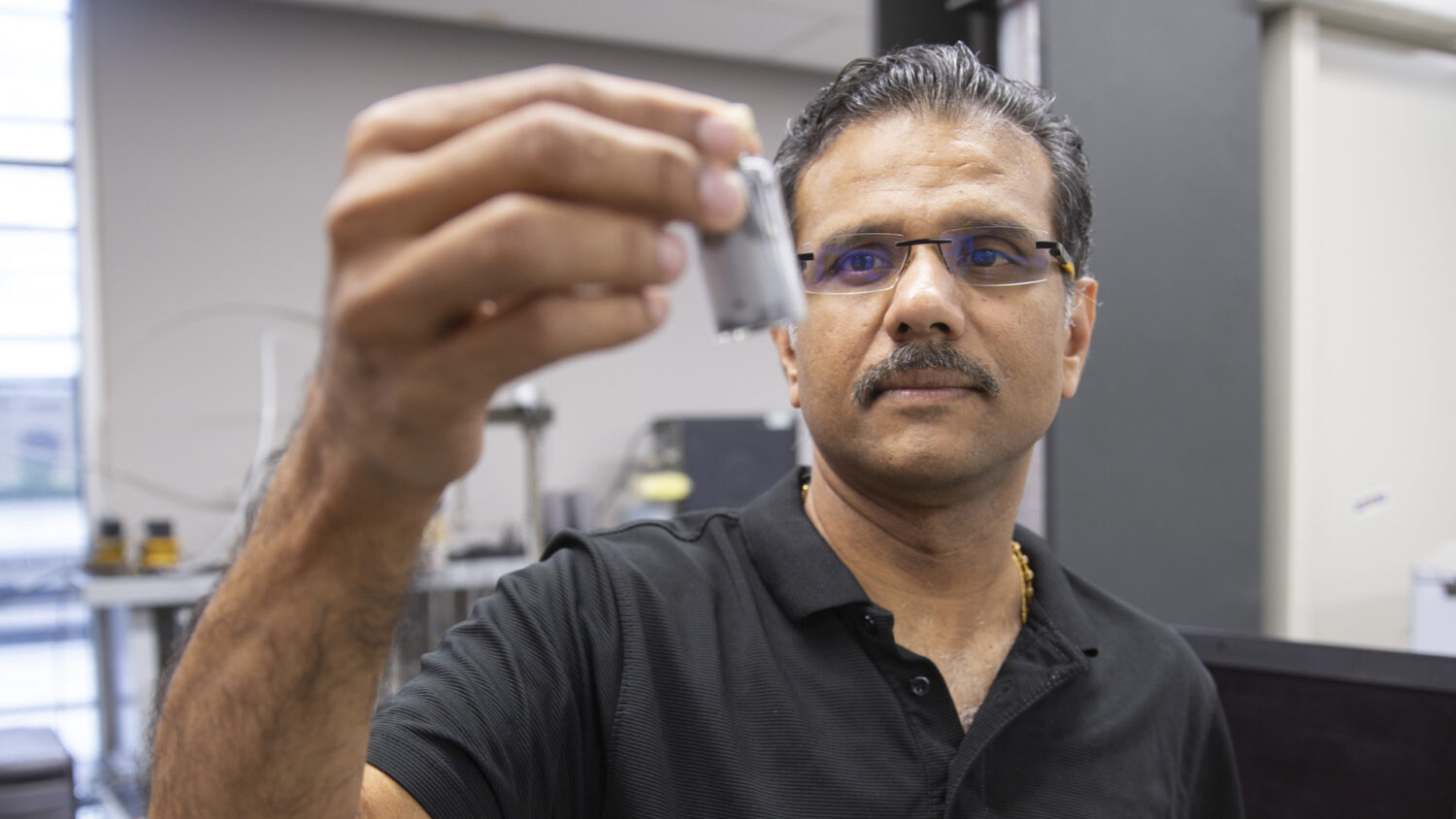

Narayanan Neithalath is a Professor in the School of Sustainable Engineering and the Built Environment at Arizona State University.

His research interests include:

- Structural materials for sustainable construction- including novel cements and cementing systems, synergistic use of reactive and filler materials, upcycling of CO2 in concrete, enhanced use of waste and recycled materials, and performance-optimized systems for desired applications.

- Manufacturing approaches for materials and structural systems for sustainability, efficiency, and economy- low energy, low carbon manufacturing of binding materials including cements, additive manufacturing of concrete, materials, geometry, and structural optimization.

- Special-performance concretes – including ultra-high performance concrete (UHPC), crack-resistant concrete through phase-change embedments, and physico-chemical and biological approaches for self-healing and enhanced durability.

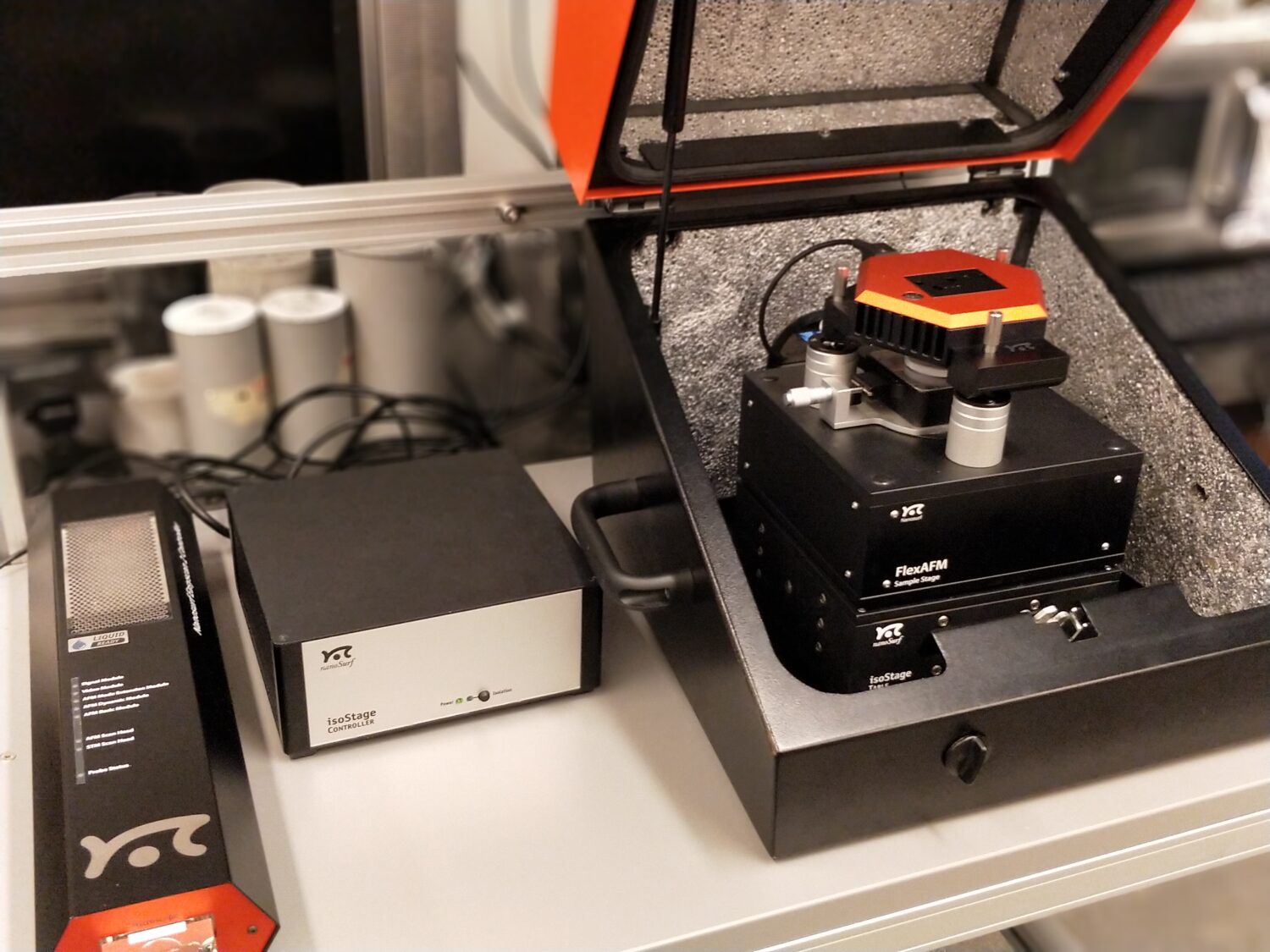

- Materials modeling for better and efficient design- microstructure-guided modeling for prediction of properties, including mechanical, transport, and coupled processes, and their control.